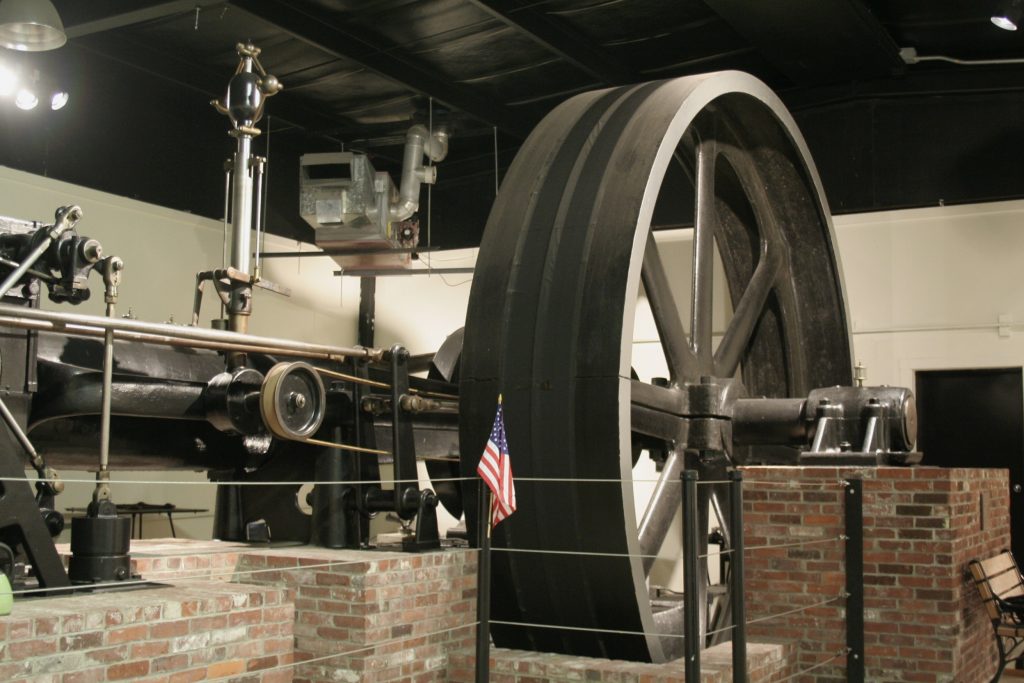

1895 Harris-Corliss Corliss Tandem Compound Steam Engine

Description

While the steam locomotive is probably the most recognizable use of steam power in history, the steam engine came in a variety of forms for many different jobs. Stationary steam engines were the first reliable power sources that did not rely on inconsistent energy sources like wind or moving water, like rivers or waterfalls.

A steam engine transforms heat energy into mechanical work. The heat energy is created by boiling water, usually with wood or coal. When one…

While the steam locomotive is probably the most recognizable use of steam power in history, the steam engine came in a variety of forms for many different jobs. Stationary steam engines were the first reliable power sources that did not rely on inconsistent energy sources like wind or moving water, like rivers or waterfalls.

A steam engine transforms heat energy into mechanical work. The heat energy is created by boiling water, usually with wood or coal. When one cubic inch of water is boiled, it becomes one cubic foot of steam. This steam occupies 2000 times as much space as the liquid.

When boiling water in a pot on the stove, all of that steam escapes into the room. But when that water is captured in the boiler, the steam builds up pressure that can do work. In a steam engine, the only path for the steam to escape the boiler is through a cylinder containing a piston connected by a rod to a round shaft with a wheel or pulley on it. When the steam is strong enough to push the piston, the rod turns the shaft with the wheel or pulley.

In the late 1830s, George Corliss was a shopkeeper in upstate New York interested in mechanical devices as a hobby. This hobby evolved into a vocation as he left the shop in 1841 and designed a sewing machine for leather. He moved to Providence, RI, a major textile center, to sell his ideas. Soon after arriving in the city, Corliss learned about the need for better engines to power the factories and shifted his focus.

Among Corliss’ inventions was the “cut off” valve mechanism that revolutionized steam engine design and made Corliss famous worldwide. The valve allowed steam to quickly pressurize a piston, moving it back and forth before the steam could condense. In 1849, Corliss patented a governor with an automatic variable cut-off which made it possible for a steam engine to use the minimum amount of steam necessary to produce the required power with no loss of speed. These innovations reduced waste heat and allowed the engine to operate with more uniform motion and lowered fuel costs. Variations on this design were used on most steam engines for the rest of the century.

In 1856, Corliss started the Corliss Steam Engine Company in Providence. His engines were produced to power factories and other industrial tasks. Scottish cotton mills imported so many engines that Corliss opened a factory in England. In Maine, steam engines drove lumber mills, clothespin factories, shoe factories, stone quarries, and machine shops.

In addition to building his own engines, Corliss licensed the technology to other companies. This engine was made by the William A. Harris Steam Engine Company was also located in Providence, RI from 1864-1915. This Harris-Corliss Tandem Compound engine powered the Cranston Print Works, a textile printing factory in business from 1824-2009. The engine, weighing 90 tons, would spin the 16 foot wheel at 80-90 rpm to produce 600 horsepower. It powered all the factory machinery from its construction in 1895 until the factory was connected to the electric grid in the mid-1900s.